FLEXIBLE SCREW CONVEYING

HOW DOES FLEXIBLE SCREW CONVEYING WORK?

A flexible screw conveyor, also known as a helix or auger conveyor, features a flexible steel screw housed in a plastic or steel tube and driven by an electric motor, typically at the discharge end. This simple, cost-effective design offers reliable and efficient material transport, outperforming many traditional conveyors like rigid screw or drag chain conveyors when properly engineered for the specific material and process.

The conveyor’s intake end usually has a charging adapter that connects to equipment like hoppers, bulk bag dischargers, or crushers. Material enters the conveyor as the screw rotates, self-centering within the tube to allow smooth flow while preventing particle damage. A removable clean-out cap facilitates easy emptying and cleaning. With the motor located at the discharge and no internal bearings at the intake, the flexible screw is the only moving part in contact with the material, reducing wear and maintenance.

FEATURES

Cost-Effective: flexible screw conveyors are economical to purchase, install, and operate due to their simple design, which lacks the expensive components found in other conveyors. The only moving part is a durable flexible screw that resists wear and requires minimal maintenance.

Flexible Design: The flexible screw and tube can be easily routed in any direction, allowing the intake and discharge to be positioned in ways that would be challenging or costly with other conveyors.

High Reliability, Low Maintenance: With no internal bearings, chains, or other complex components, flexible screw conveyors offer exceptional reliability and minimal maintenance needs. They can handle full loads, including moist or dense materials, without binding or damage.

Single Moving Part: The only material-contacting component is the flexible screw, driven by an electric motor, which self-centers within the tube to maintain clearance and avoid wear. This design eliminates the need for additional moving parts, reducing costs and maintenance.

Versatile Conveying: Unlike other conveyors with limited angles or straight-path restrictions, flexible screw conveyors can transport materials vertically, horizontally, or at any angle, easily navigating around obstacles.

Gentle Handling and Blending: The self-centering screw provides ample clearance to prevent product damage, while the gentle rolling action maintains the integrity of blends throughout the conveying process.

CLEANLINESS

Contamination-Free: The fully enclosed design of a flexible screw conveyor ensures a dust-free and mess-free operation, preventing contamination and maintaining the moisture and temperature of conveyed materials.

Easy Cleaning: With no internal crevices or bearings, a flexible conveyor is easy to clean. Simply remove the clean-out cap, reverse the screw to clear any residue, and flush with air, water, steam, or cleaning solution. The screw and tube can be quickly disassembled for thorough cleaning.

Hygienic Standards: flexible conveyors are available in carbon or stainless steel with finishes that meet industrial, food, dairy, or pharmaceutical cleanliness standards, including 3-A compliance.

OPTIONS

High Flow Hopper for Enhanced Material Flow:

Flexicon's High Flow Hopper, designed specifically for flexible screw conveyors, improves the flow of both free- and non-free-flowing materials, reducing the need for flow-promoting devices and minimizing residual material. Its trapezoidal shape with steep and outward-skewed walls prevents material bridging, directing it efficiently toward the conveyor. This design increases usable hopper capacity by 5 to 19 percent and reduces leftover material by up to 100 percent.

Volumetric Feeding:

Flexicon flexible screw conveyors with volumetric controls offer precise metering and conveying of bulk solids. Equipped with variable speed drives and flow-promoting hoppers, they ensure continuous feeding of both free-flowing and non-free-flowing materials.

Free-flowing and non-free-flowing materials and blends

![]()

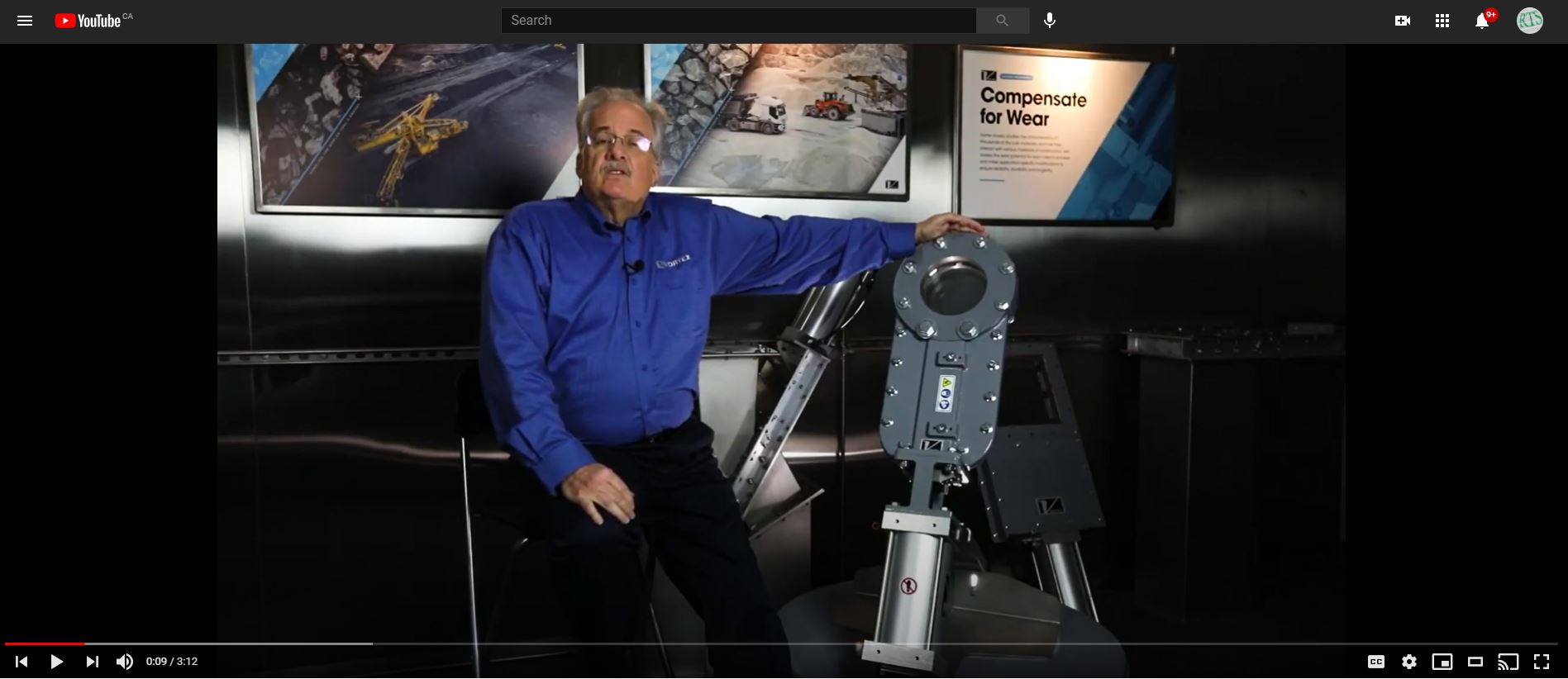

Rugged flexible screw is the only moving part contacting material, moving free-and non-free-flowing materials that tend to pack, cake or smear, with no separation of blended products. It is driven above the point at which material is discharged, preventing material contact with bearings or seals. Small to wide diameter screws in many geometries handle low to ultra-high capacities.

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...

Lorem ipsum dolor sit amet consetetur Elit

Lorem ipsum dolor sit amet dolor, elit consectetuer adipiscing elit. Donec odio. Nullam malesuada erat ut...