Britech provides engineered and standard heating cables to home builders, manufacturers, tile installers, renovators, consulting and engineering firms, federal and provincial governments, major industrials and more.

Britech provides engineered and standard heating cables to home builders, manufacturers, tile installers, renovators, consulting and engineering firms, federal and provincial governments, major industrials and more.

Britech's heating cables are crafted to efficiently control and increase temperatures for pipes, tanks, and a variety of equipment. In cold climate regions, these cables are essential in numerous industrial applications.

An extensive array of cables designed for maintaining process temperatures and preventing pipe freezing are available, in addition to snow melting.

Protect your entire installation from freezing pipes, roof and gutters, surfaces and walkways, ramps, floors and drains.

Our range of self-regulating heating cables offers a flexible solution to prevent heat loss in pipe and piping systems, including those used for potable water. This technology is compatible with both metal and plastic pipes, can be cut to the required length on-site, and can be overlapped safely without the risk of overheating.

Freeze Protection for Pipes

Preventing pipes from freezing helps prevent costly damages and disruptions caused by burst pipes.

Temperature Maintenance

Heating cables effectively regulate the temperature of pipes and vessels transporting viscous materials, chemicals, or other temperature-sensitive substances.

Roof & Gutter De-Icing

By installing heating cables on roofs and gutters, you can effectively prevent the accumulation of ice and snow, thus safeguarding against potential structural harm and dangerous situations.

Frost Heave Protection

In areas prone to ground freezing and structural damage, heating cables offer protection against frost heaves by keeping the ground temperature above freezing in cold storage facilities and other vulnerable locations.

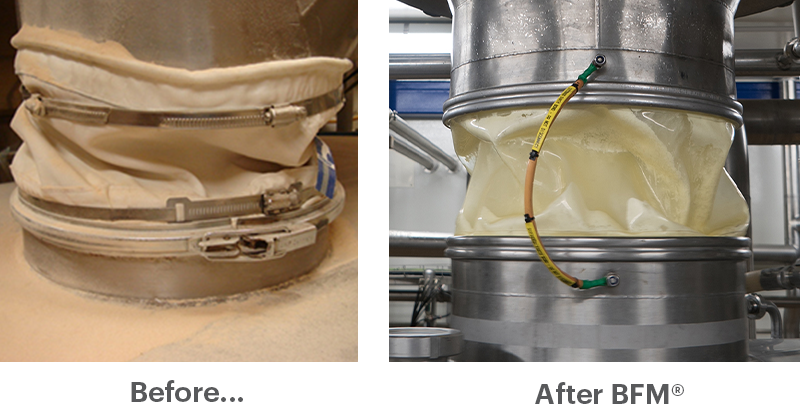

This case study examines the implementation of heating cables in a major dairy manufacturing plant located in the Midwest, USA. The project,

spanning 9 months from January to September, aimed to ensure continuous and efficient processing in critical areas subject to low

temperatures. The primary objectives were to prevent pipe freeze-ups and maintain consistent temperature control in fluid transport lines, thereby safeguarding the quality and safety of dairy products.

This case study examines how a mid-sized commercial bakery in New York, USA, implemented self-regulating heating cables to address issues with inconsistent heating and temperature control. The study details the implementation process, cost analysis, and data-driven results of using these cables in a commercial bakery environment, demonstrating significant improvements in efficiency and cost savings.

Britech provides engineered and standard heating cables to home builders, coal and nickel mines, tank manufacturers, major oil companies, tile installers, renovators, consulting engineering firms and federal and provincial governments, etc.

Contact Ryan - ryan@ratetechnology.com

to learn how Britech heating cables can benefit your operations.