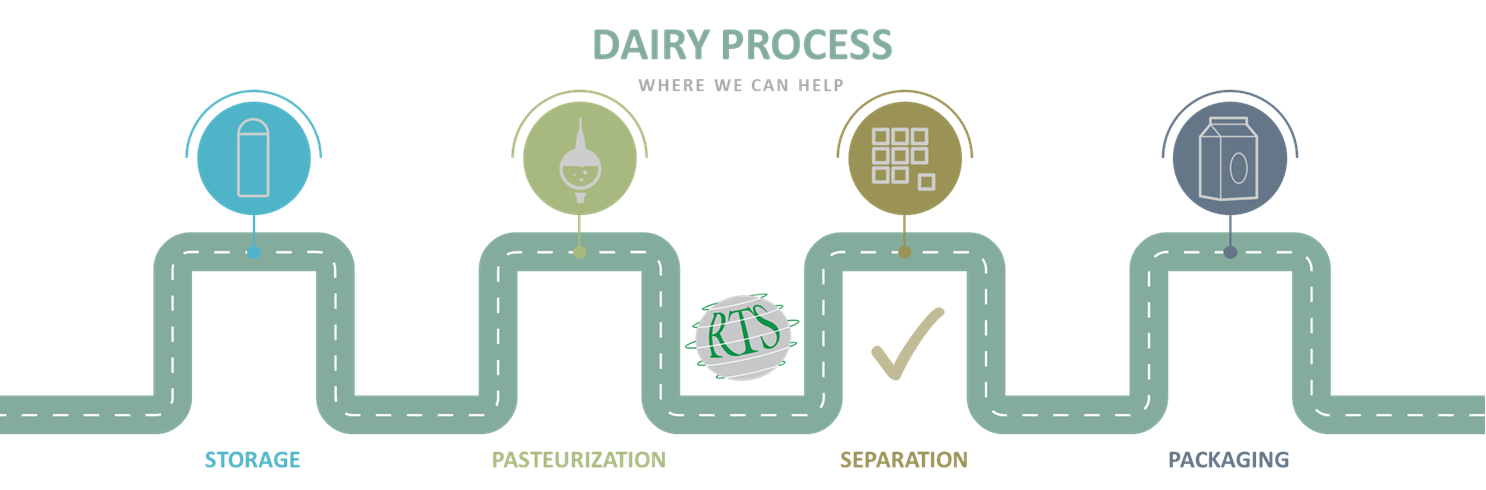

DAIRY PROCESS

Air Classifier Mill

Dairy plants use Air Classifier Mills for Ultra-Fine and Controlled Particle Size Grinding

Air Classifier Mills incorporates an internal air-classifying wheel with an independent drive giving precise control over “particle cut point” selection. Suitable for batch processing or continuous operation. This range of mills serves all industries producing fine powders where control of grinding temperature and particle size distribution are of primary importance.

PPS Air Classifier Mills are high energy grinding mills with an integral classifier to produce ultra-fine powders.

Features Include:

- High Energy Controlled Grinding

- Integral Classifier for a Finer Powder

- Tight Particle Size Distribution

- Large Range from 5hp to 400hp

- Easy Clean ‘Clam-Shell´ Body Option

Product Range

PPS Air Classifier Mills are available in a large range of sizes, from small lab pilot units through to 400 hp production units.

PPS Air Classifier Mill Range

| Model | Main Drive Power | Classifier Drive Power | Approx. Airflow |

| Lab CMT | 1.5 hp | 1 hp | 175 cfm |

| 1 CMT | 5.5 hp | 1 hp | 500 cfm |

| 2 CMT | 10 hp | 2 hp | 700 cfm |

| 3 CMT | 15 hp | 3 hp | 1000 cfm |

| 4 CMT | 30 hp | 5.5 hp | 2500 cfm |

| 5 CMT | 40 hp | 7.5 hp | 3000 cfm |

| 6 CMT | 60 hp | 10 hp | 5000 cfm |

| 7 CMT | 75 hp | 15 hp | 6000 cfm |

| 8 CMT | 200 hp | 30 hp | 11750 cfm |

| 10 CMT | 300 hp | 60 hp | 18000 cfm |

| 12 CMT | 400 hp | 75 hp | 24750 cfm |

Applications

PPS Air Classifier Mills provide ultra-fine grinding of powders with a controlled particle size distribution.

Typical Applications include:

Food Industry

- 12X and 14X Grade Powdered Sugar

- Gluten

- Ultra-Fine Flour

Chemical Industry

- Dye Powders

- Toner Powders

- Dry Sorbent Powders

- Talc

Pharmaceutical Industry

- Ultra-fine Grinding of Active Pharmaceutical Ingredients.

Custom Design

PPS Air Classifier Mills benefit from versatile design capability, which can be customized to suit the demands of individual applications.

This includes:

- Temperature Controlled Grinding

- Cryogenic Milling

- Inert Milling

- Explosion Protection

- Explosion relief through Bursting Panels

- Explosion suppression with a Quench System

- Explosion containment with 10 bar PSR design

- System inerting by replacing combustible gases and air with inert gas such as nitrogen

In addition, PPS Air Classifier Mills benefit from flexibility of design, allowing systems to be customized to fit into all types of physical layouts.

Cleaning and maintenance of the PPS Air Classifier Mill system is enhanced by:

- Clam-Shell design mill body for easy access to the grinding chamber

- Pressure capable quick-release pipe connections

- Replaceable grinding pins, bars and hammers

- Replaceable classifier wheels

- Replaceable mill liners