A More Effective Alternative

In the most challenging industrial settings, where top-notch performance and efficiency are non-negotiable, the answer is crystal clear. SDC delivers nothing short of the ultimate solution - thanks to you. We deeply value our customers and prioritize resolving their real-life predicaments. Through continuous research, hands-on experience, and cutting-edge technology, we thrive in today's fiercely competitive global market.

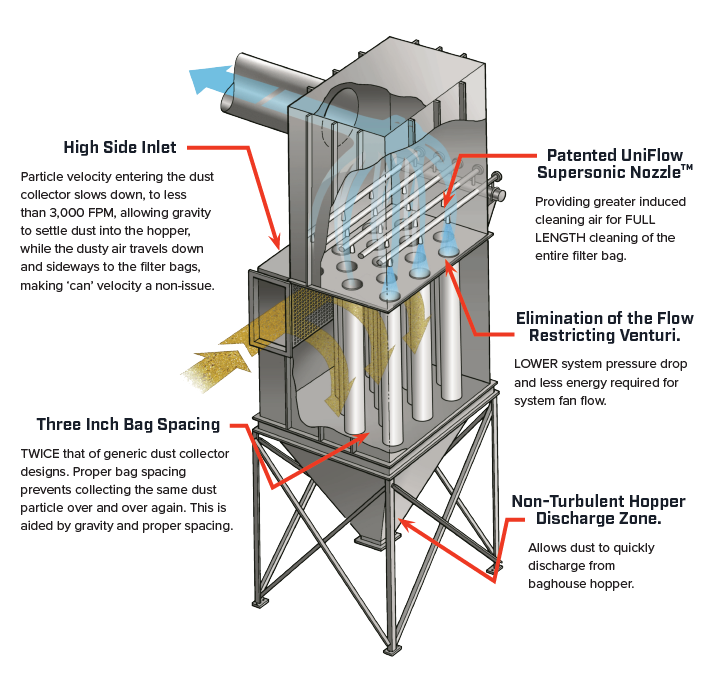

Scientific Dust Collectors takes pride in providing a cutting-edge and advanced solution to dust collection. By delving deep into the realms of scientific principles like velocity, gravity, and pressure, we have mastered the art of engineering highly efficient dust management systems. Our sophisticated alternative to the generic dust collector guarantees optimal performance and sets us apart in the fiercely competitive global market.

Experience the Difference with Scientific Dust Collector’s Revolutionary Cleaning System. Our patented technology not only effectively cleans the filter bags but also promotes a uniformly distributed dust cake along the entire length of the filter bag. This innovative approach allows us to require significantly less cloth area compared to generic dust collectors that rely on venturi-based cleaning systems. Don't settle for poor cleaning and excessive cloth area; choose the smarter solution for your filtration needs.

Improving the Cleaning Cycle in Baghouse Collectors

The reverse pulse jet baghouse has been around for over 45 years and the cleaning cycle has not changed very much since that time. The cleaning cycle is the most important part of the dust collector because it controls efficiency and media life.

Advantages of Cleaning without a Venturi In Pulse Jet Baghouse Collectors

A venturi has been associated with reverse pulsejet baghouse dust collectors since the 1950’s, and has become the industry standard design for the reverse-jet cleaning system of baghouse dust collectors. While the reverse jet with venturi does provide some advantages when compared to other methods such as reverse-air or mechanical-shaker cleaning systems, the venturi itself has some disadvantages that are often overlooked.

New Nozzle Technology | Cleaning More With Less

This technical paper will explain the new nozzle technology developed by Scientific Dust Collectors that allows high air-tocloth ratio baghouses to use 80psig of compressed air instead of the industry standard 100psig.

This is the first time a definitive test method has been identified for the dust collection industry. Standard 199-2016 was published as a joint venture between ASHRAE and the American Standards Testing Institute (ANSI). ANSI/ASHRAE Standard 199-2016 specifies test methods to measure emissions, differential pressure and compressed air consumption in pulse cleaned dust collectors under realistic operating conditions. It applies to bag, cartridge, or envelope style industrial dust collectors that clean the filter media by using a pulse of compressed air to discharge the dust cake from the filter media while the air cleaning device remains online.

The test procedure is not concerned with the internal operation of the dust collector itself, but rather the actual performance of each testing process. For too long, the use of the MERV rating has been associated with dust collector performance. This can’t be farther from the truth as the MERV rating is specific to filter media performance under controlled laboratory conditions that mimic industrial HVAC systems. While the MERV rating is useful for HVAC systems, it does not take into consideration the performance of repetitive cleaned filter elements.