Rate Technology Systems

Material Handling Specialists | Achieving Significant Production Efficiencies Is Our Strength

Equipment By Industry

Specializing in providing complete materials handling (powder, tablet and API) solutions for OSD and API pharma manufacturers.

We have processed every chemical imaginable, from the coatings and textiles sector, plastics, petrochemcial, paint and coatings, to fertilizers and more.

Helping our customers hygienically process their products. Dairy, fruits and vegetables, grains, vegetables, beef, poultry and fish, sugar, coffee, seasonings, vitamins, beverages, pet food. Our food processing experience is extensive.

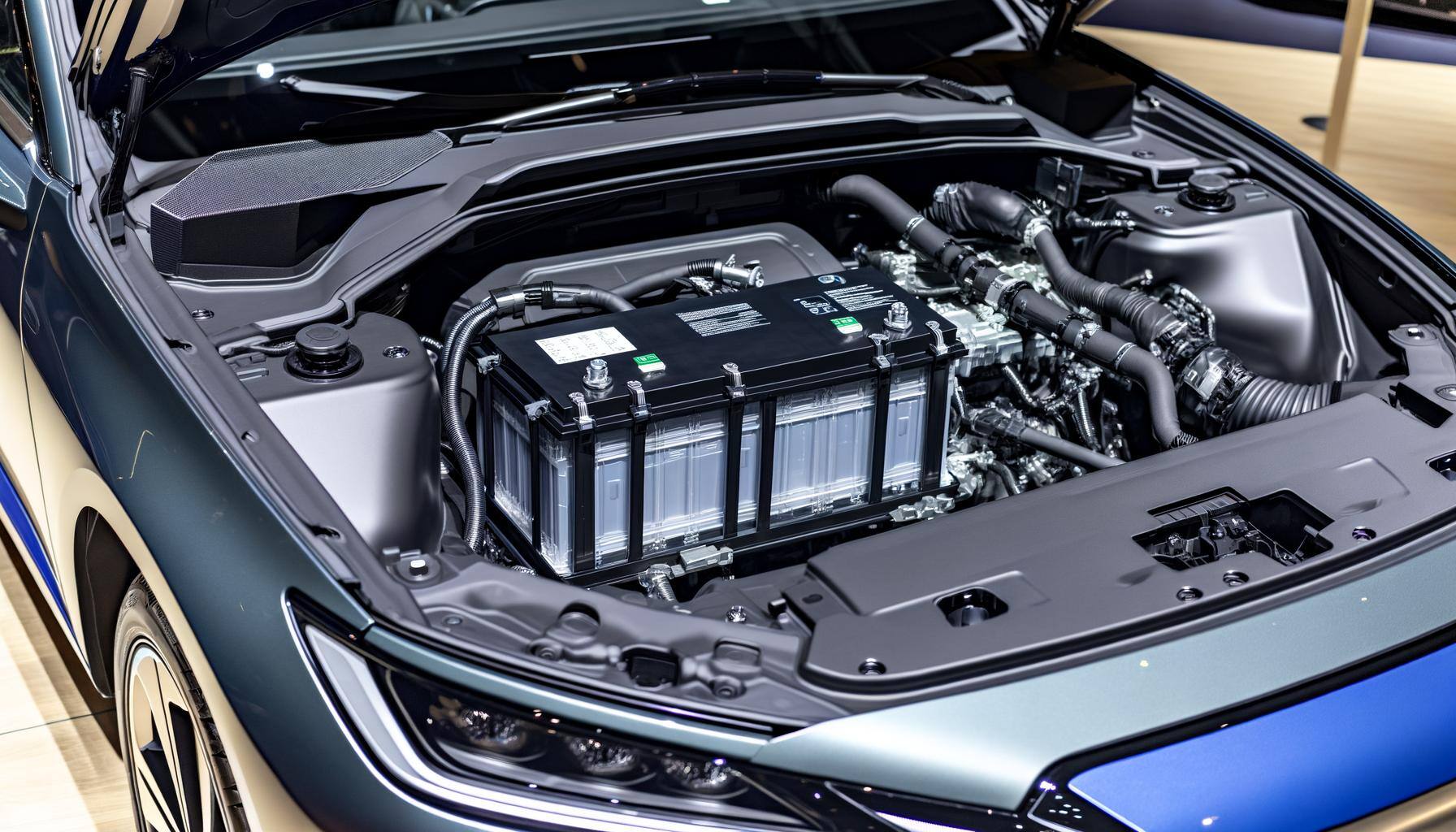

Supporting manufacturers of Alternative Fuels and Bio Process - helping to do our part to support the environment and sustainability.

We work very closely with engineering and consulting groups to ensure each client’s individual process needs are met and satisfied.

No matter what you're processing, we represent one of the most innovative systems to support mining initiatives.

We support the housing and commercial construction industry by working directly with manufacturers of cement, concrete, brick, wood, composites, steel, gypsum and fiberglass to achieve significant production efficiencies.

We have processed a variety of these pastes, liquids, powders, granules and solid melts, which are used for the construction and home improvement spaces.

Latest Blog Posts

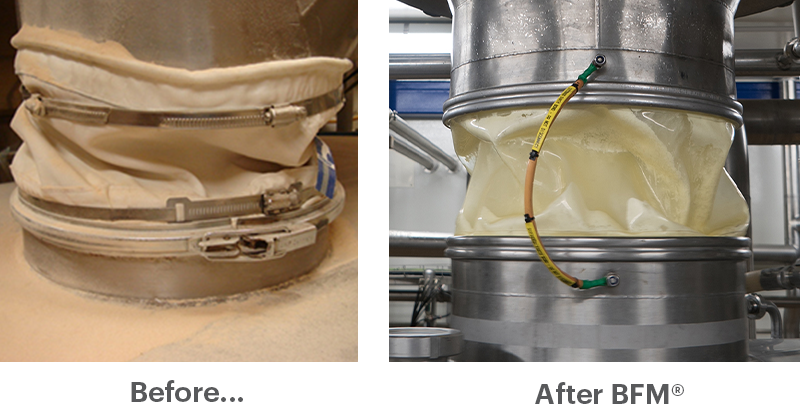

Premium Flexible Connectors are crucial in ...

How Air Classifiers Solve Material Separation ...

Efficient Level Control in EPS Industry

Design Solutions for Abrasive Applications

Efficient silo management for smooth process flow

Humanitarian Food Relief Increased Sevenfold with ...

Decorative Concrete Producer Takes Blending ...

Flow Control Valves & Much More!

What is an Electromagnet and How do they Work?

Flexible Connectors Influence Your 3-A Food ...

And you know what the best part is?

We're a proudly Canadian, family owned business.